Core Competencies

PM is an independent business with over 55 years of highly specialised experience in the design and manufacturing of precision linear bearings, frictionless slides and positioning systems.

Serving a global client base on the cutting edge of high-tech industries, our products are an integral part of the market’s constant push to develop the most innovative solutions. We are proud of our continued success in attaining our position as a trusted partner and architect of high-performance linear bearing systems, crossed roller configuration technologies, motion systems and integrated solutions.

We are masters in solving complex technical problems. We apply deep mechatronic expertise and the latest manufacturing know-how to our clients’ specific industry challenges.

Product Lifetime Management

PM has adopted a Product Lifetime Management (PLM) system supported by Siemens NX and Teamcenter, that helps us deliver on our core values of structured development and continuous product support.

Our mechanical and mechatronic system engineers use the latest 3D CAD and FEA tools, and design revision management is at the heart of our approach. In close cooperation with the customer, we can therefore quickly and effectively modify existing products or develop entirely new products. This integrated PLM environment also ensures seamless data flow between departments, improves traceability, and enhances collaboration throughout the entire product lifecycle, from concept to serial production and long-term service.

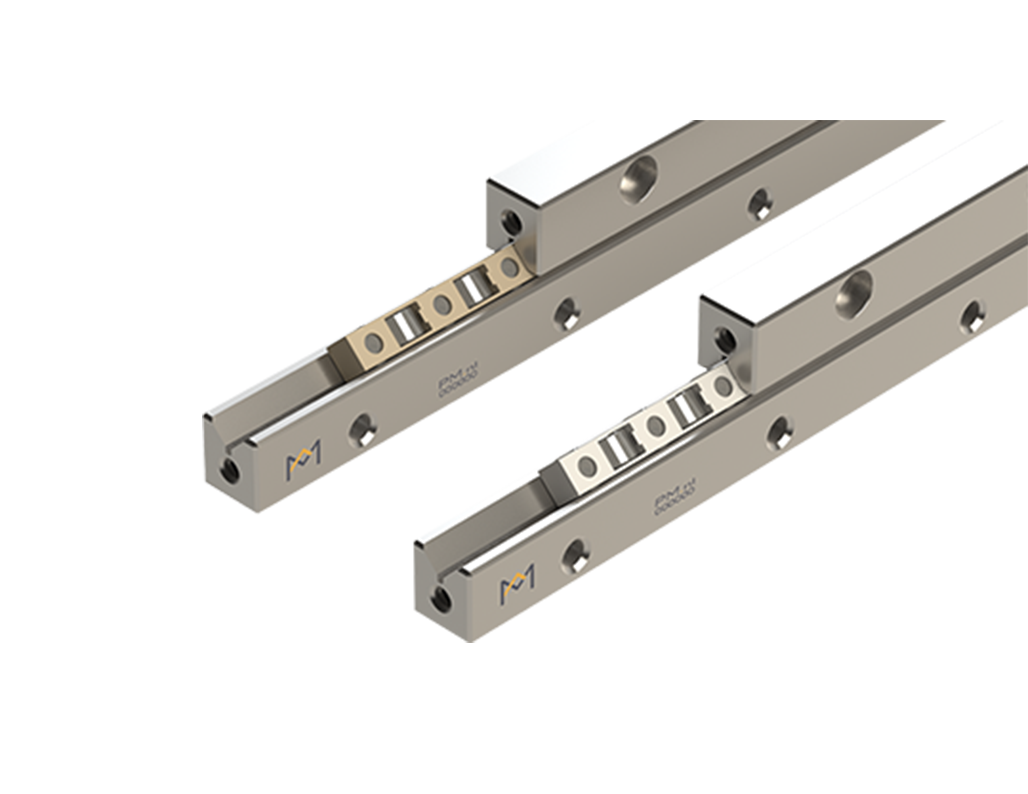

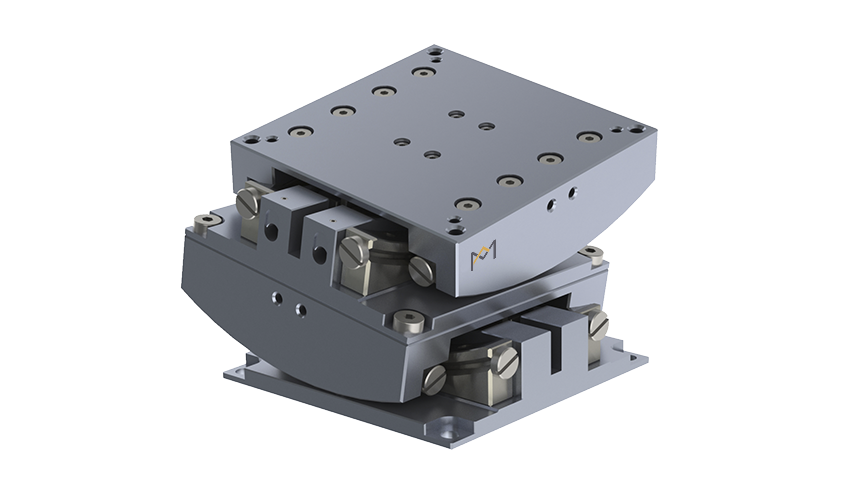

Catalogue-listed and custom made

Over time, PM has developed an impressive range of standard catalogue-listed products which are readily available to order. The product catalogue lists a wide range of crossed roller bearing types as well as circular and recirculating precision bearings. In addition, our standard inventory includes motorised stages driven by a variety of different types of motors. By stacking these modules, cost-effective stages can be configured.

PM offers customisation of standard models or a complete product redesign to meet unique customer specifications.

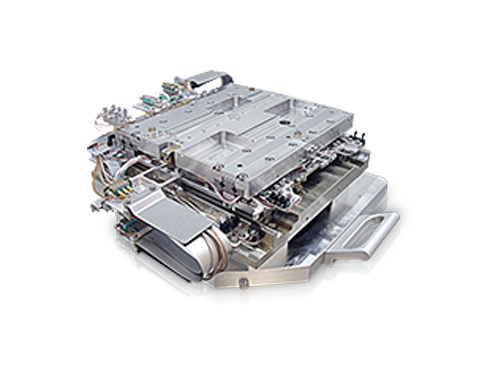

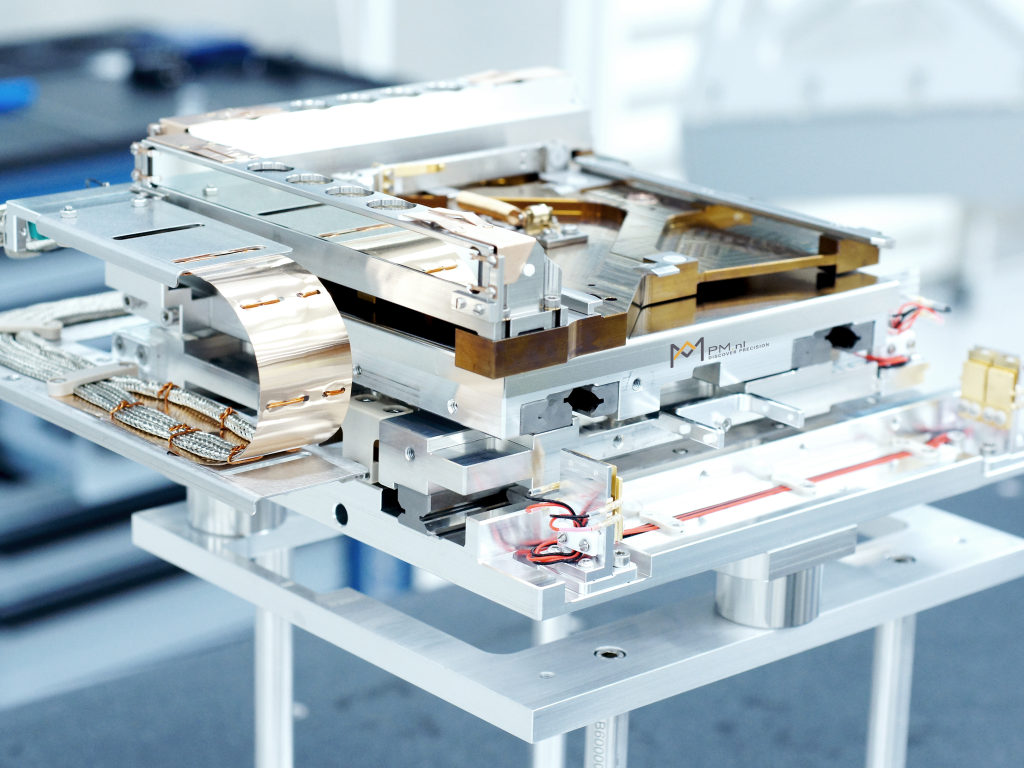

Motion system development

Custom motion system development is available for PM customers with demanding product specifications or unique application requirements. From the initial concept to final production, our team supports you throughout the entire process.

To ensure our products perform according to specification, we adopted the well-known V-model in which system concepts are evaluated and customer specifications are translated into engineering specifications through our Multibody Dynamics Model which was developed in-house. Subsequent designs for sub-systems are validated ensuring they all work in synergy when assembled as a whole.

Manufacturing expertise

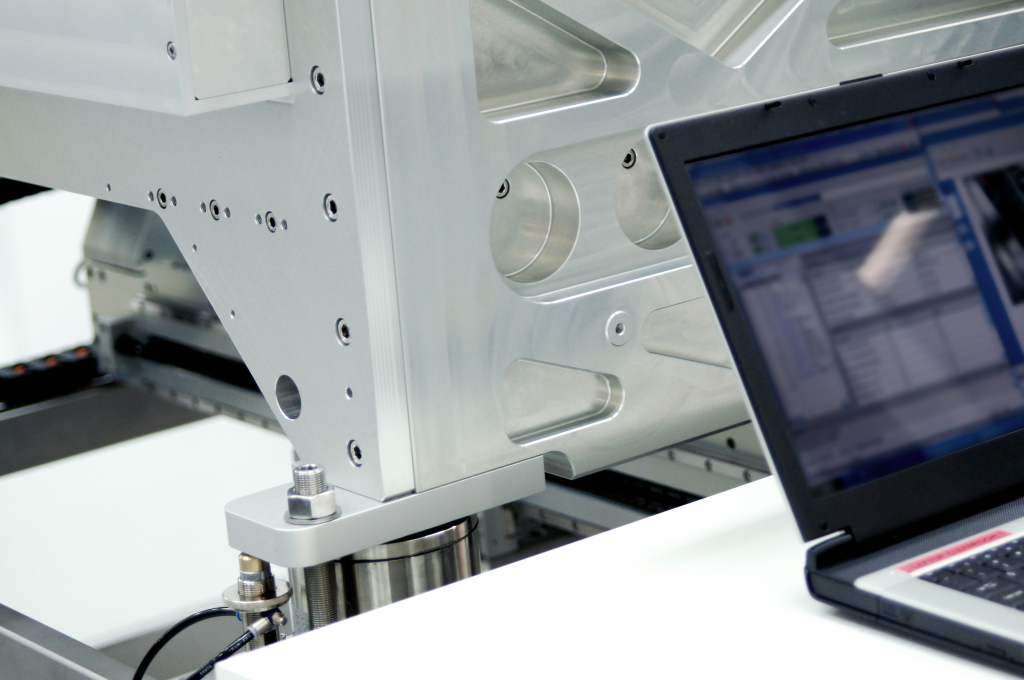

PM facilities can accommodate production at various levels of magnitude: from prototyping or sampling batches to moderate or high-volume production. With production models like Kanban and J-I-T integrated into our ERP system, we remain resilient in the face of demand fluctuations.

Having our own production plant gives us full control of manufacturing processes like high precision grinding, milling, and material hardening, which ultimately improves the overall product quality. This in-house capability also enables rapid adjustments, efficient process optimisation, and the consistent delivery of high-precision components that meet the strictest industry standards.

Large machining

With our large machining department, we are able to produce complex and large parts for the semiconductor, aerospace and defense industry. The climate-controlled facilities are built to the latest standards. Our largest CNC milling machine, the Matec-40P, has a working area of 10500 x 3400 x 1350 mm.

We are able to produce parts in several types of materials, e.g. titanium, ceramics, stainless steel, composites, aluminium and more.

Vacuum technology

PM has extensive experience in the design and manufacture of HV and UHV chambers and components. Working with specific design tools for vacuum applications and applying our know-how of materials optimised for vacuum applications, we can offer a complete, cost-effective solution, perfectly suited to the customer’s specific needs.

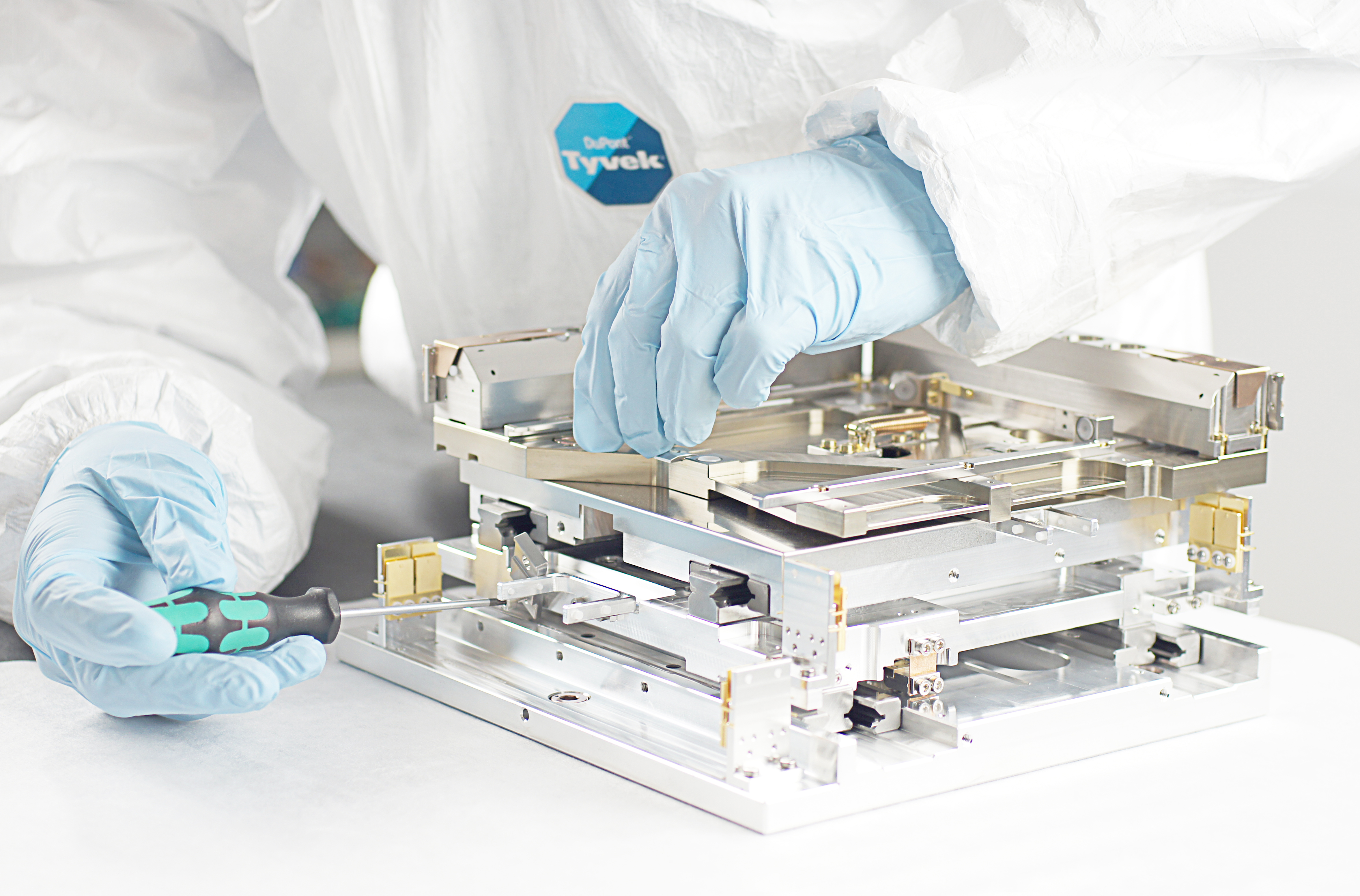

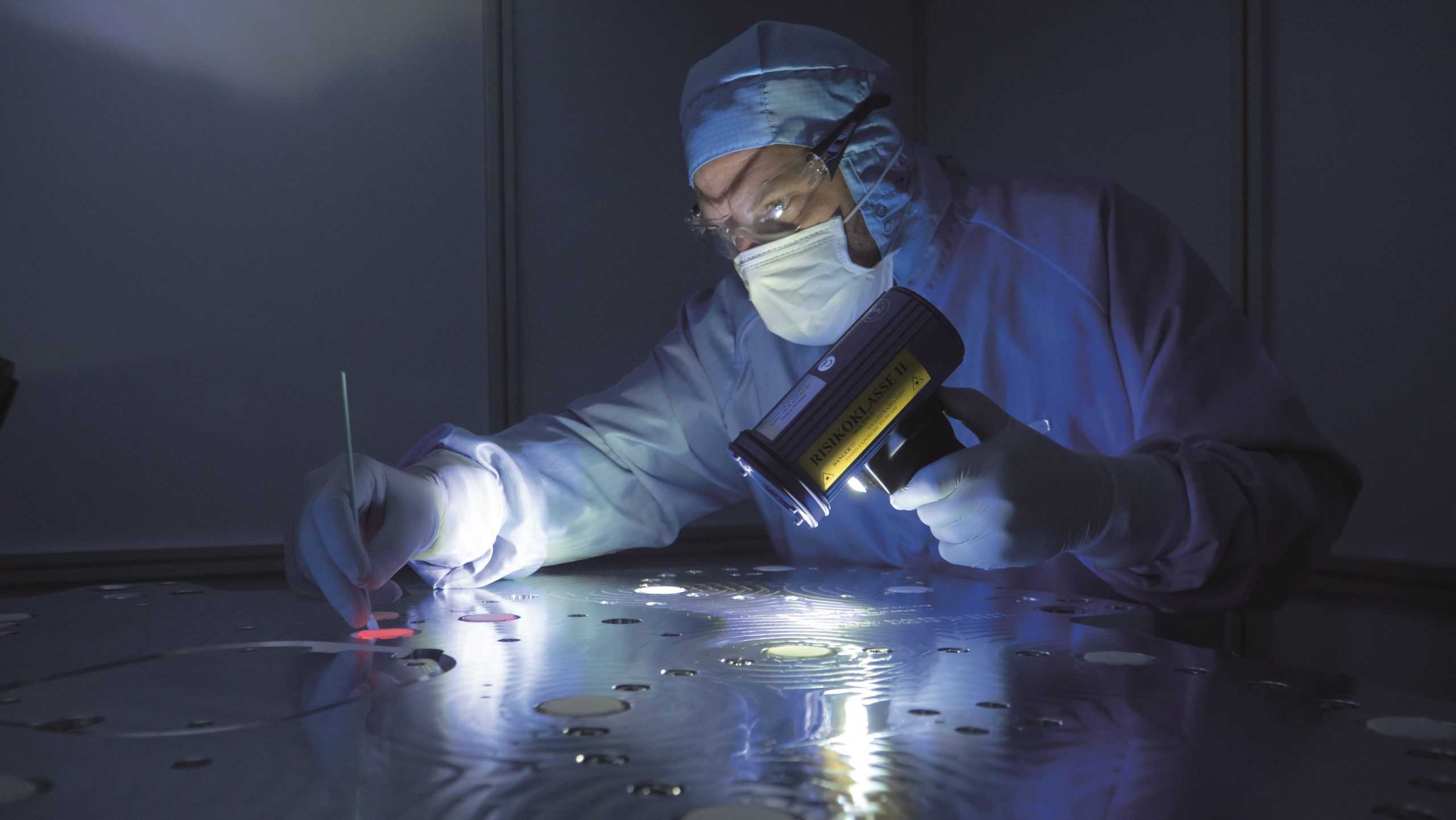

Cleanroom facilities

With our ISO Class 6 certified cleanroom facilities, PM is well equipped to meet industry’s requirements of today and tomorrow. In our 1500m2 (15000 sq. ft.) cleanroom we can assemble, test and package components and systems, making them ready for cleanroom application at the customer.

RGA capabilities

For the most clean environments we ensures ultra-clean components by combining bake-out in our ovens for small and larger parts, with a Residual Gas Analysis (RGA). Even the smallest molecular contaminants can be detected, ensuring that parts and positioning systems meet the cleanliness requirements.

Application examples are in life science and semiconductor manufacturing such as electronic microscopy, wafer lithography and mask writers.

Development of computational tools

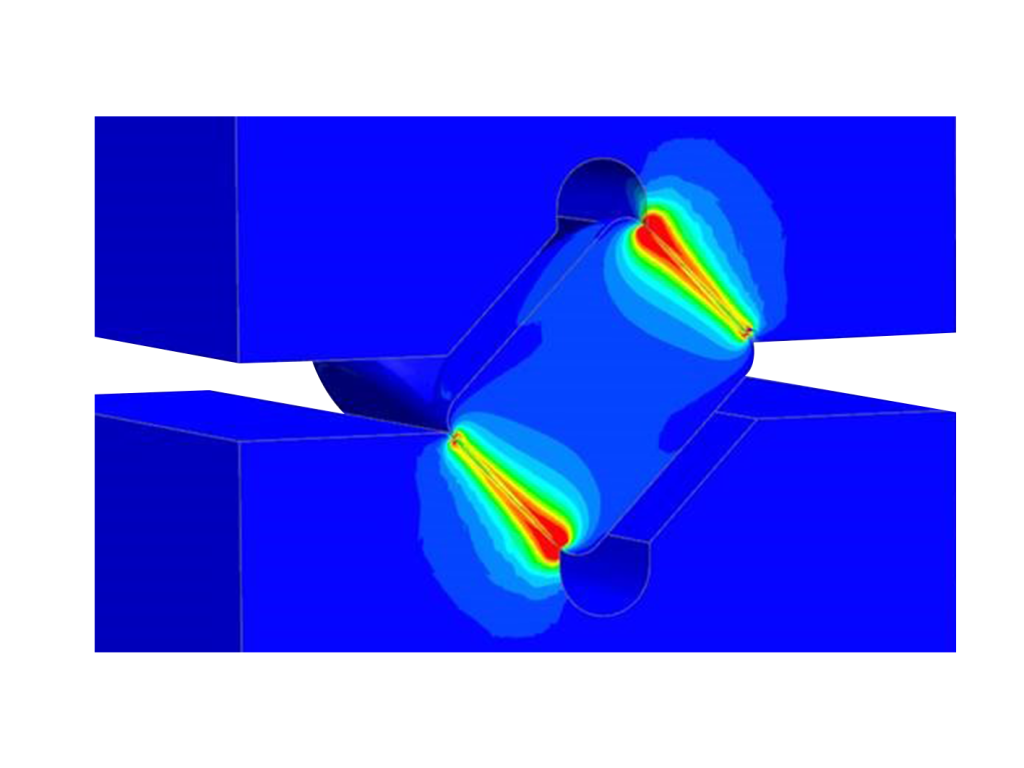

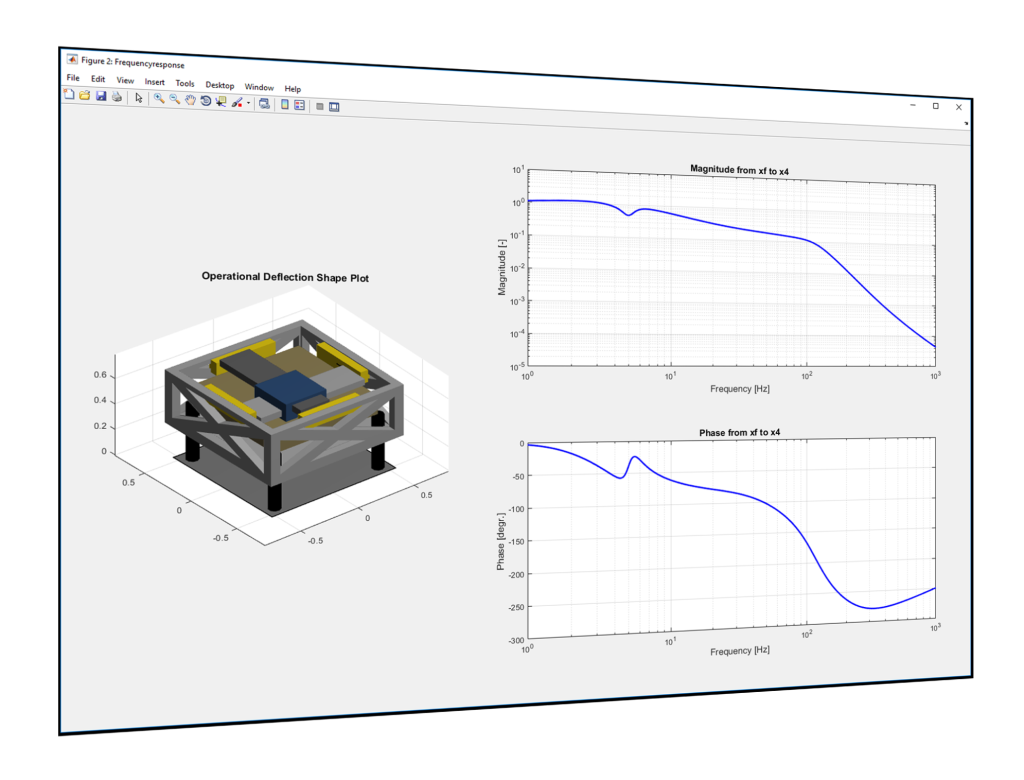

As an integral part of our R&D activities, PM continuously develops new computational tools as they are needed in current or future design and qualification efforts. Among the major benefits of developing these tools in-house are being in full control over the process and outcomes, a naturally obtained thorough understanding of various model outputs and the assurance of suitability to PM’s specific needs. Many of these models are MATLAB-based. A few examples of tools we developed are:

- Nonlinear bearing stiffness calculator

- Topology optimisation routine

- Constrained multibody dynamics simulation programme

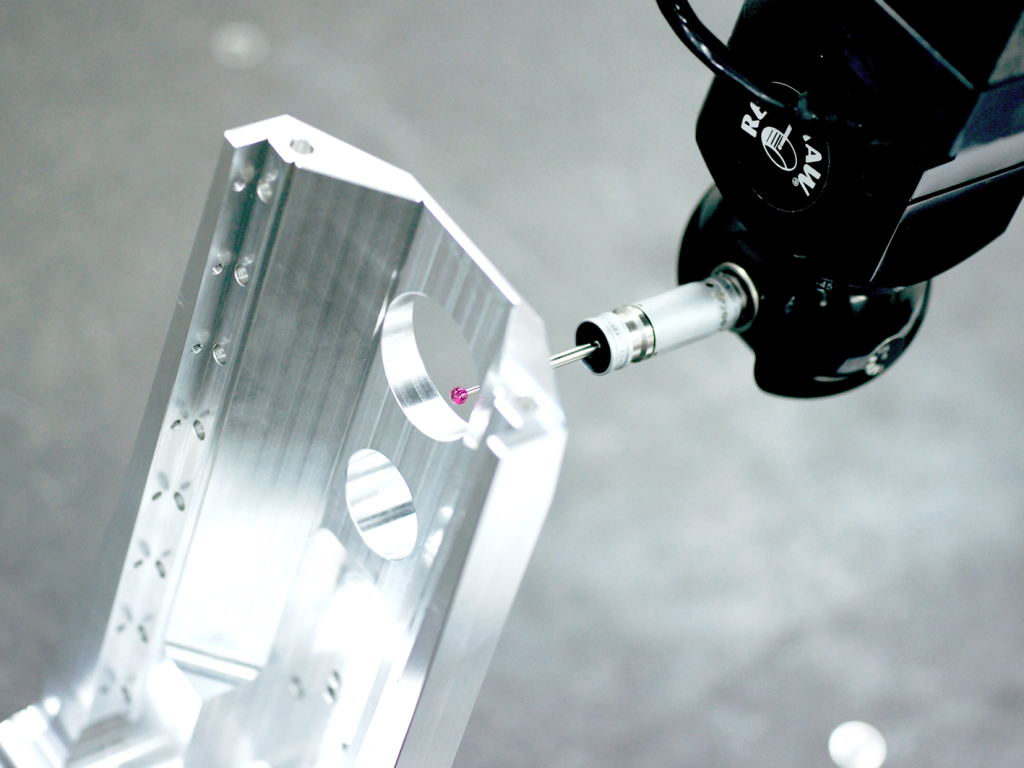

Qualification and testing

We possess a variety of equipment for qualification and testing of our wide product range. On a component level our profilers, coordinate measurement machines and optical instruments provide valuable insights, while on the system level our dynamic testing equipment allows us to identify machine frequency responses, to identify mode shapes and to specify operational parameters, even at the customer’s location if so desired.

Quality control

High product quality is a key goal for PM, which we achieve and safeguard through the application of risk mitigation and process control methods throughout the entire production chain, from conceptual design to final testing and qualification. Specifically, we make use of statistical process control, FMEA, 8D and constant multi-level internal reviews to maintain our high standard of product quality.

Highlighted products