Over 55 years of experience

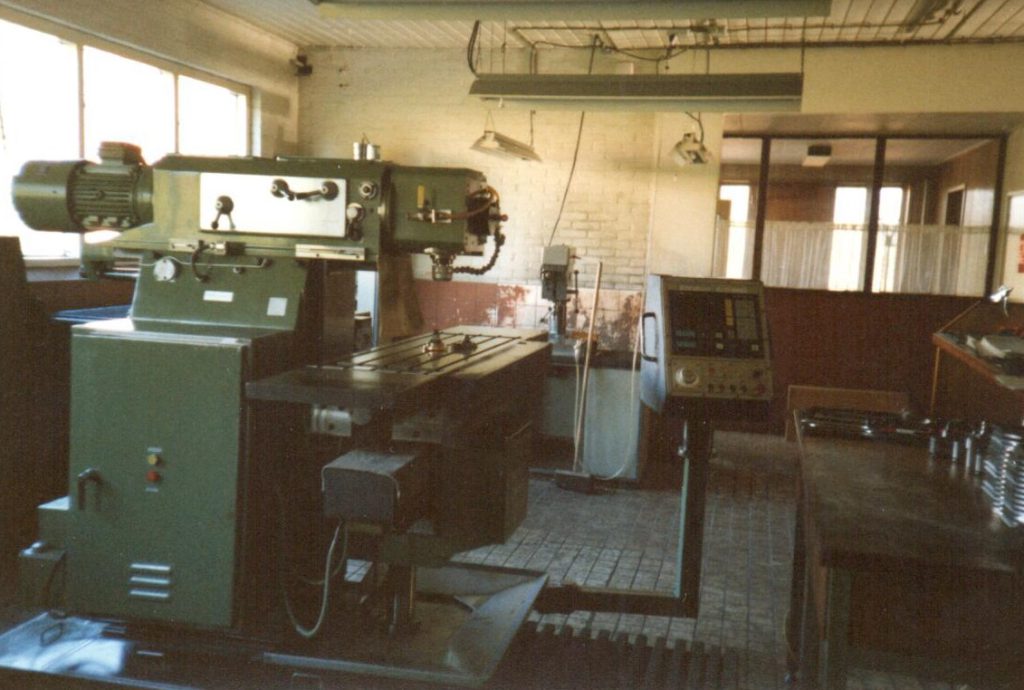

As one of the first manufacturers of linear crossed roller bearings in the world, the company’s pioneering spirit was present right from the start. The original PM workshop for precision tooling and mechanics opened in 1966 in Dedemsvaart, the Netherlands. Already during its early years, PM enjoyed steady growth by focussing on high-tech markets.

1960s

PM was founded in 1966 as a family-owned company named Precisie Metaal (English: Precision Metals) and has proudly remained an independent business ever since.

From the outset the company’s core values have relentlessly been built around high-quality machinery and true craftsmanship. These have been the foundation for PM’s long tradition of quality and precision design and manufacture. To this day, at PM we continue to beat our customers’ expectations as continuous investment in our engineering and production processes translates into more ambitious product specifications.

1970s

In the 1970s the company’s steady growth trajectory meant an increase in staff numbers and a continuing focus on innovation in our design and machining processes. While our scale has increased, however, we have never lost sight of our key goal to keep individual team members actively involved throughout the entire product lifetime process. We continue to see this as crucial to our ability to deliver products that are tailor-made to our customers’ needs.

1980s

In the 1980s PM outgrew its original premises and moved to a new site. The move coincided with the development and production of our first non-standard linear bearings made to customer specification. Towards the end of the decade, our strong pioneering spirit and engineering enthusiasm had let to the development of the RPM rotational bearing type; a real novelty in its day. This bearing is renowned for its accuracy and high repeatability.

1990s

A change of ownership in 1999 accelerated the pace of innovation in miniaturisation and automation. A renewed focus on miniature (PMM) slides, systems and the automation of its production process resulted in the development of our high volume production capacity whilst also maintaining product quality at the highest levels. This transformation firmly cemented PM’s position as an international player in the field of precision positioning equipment, with the production capacity to match.

2000s

As PM continued to innovate and expand its expertise, the company once again outgrew its facilities. In 2004, a new chapter began with the move to its current location, a modern 13,000 m² production plant featuring an ISO class 6 cleanroom and state-of-the-art office spaces.

The new environment not only provided room to grow but also inspired further innovation and collaboration. It marked a turning point that accelerated PM’s ability to attract new customers, strengthen partnerships, and expand its presence on a global scale.

In line with the company’s strategic vision of our future trajectory, at the start of the twenty-first century PM started to focus on integrated motion and positioning solutions, with mechanical high accuracy linear bearings as our backbone.

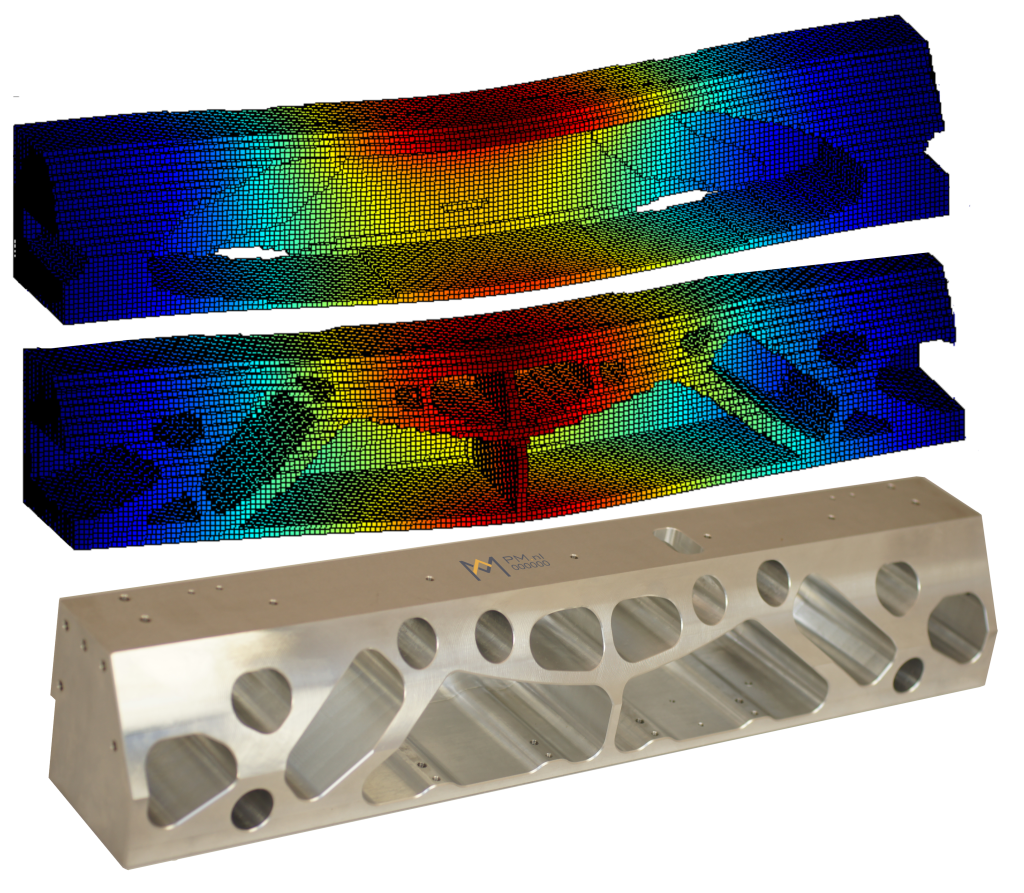

Today’s focus on R&D and engineering

PM’s multidisciplinary approach to system design unites competencies in the areas of mechanical, control and mechatronic system engineering into a system-oriented approach. This approach is geared to exploiting the maximum potential of PM precision products in their various industry applications, and specifically those benefiting from nanometer precision positioning. As an integral part of the engineering team, our dedicated R&D department ensures innovation in high-tech positioning systems is always in front of our mind.

PM has ongoing cooperations with research and higher education institutes throughout the Netherlands and regularly takes part in national and regional innovation incubation programmes in order to maintain close links with the wider research community as well as the engineering industry’s next generation of talent.

Continued expansion

In 2014 we doubled the space at our current facilities and invested in new automation for around-the-clock production. We also extended our cleanroom facilities, invested in a state-of-the-art ERP system and improved our design software.

Milestone

In 2017 PM reached a milestone with the manufacturing of the 100,000th micro slide PMMR; a milestone that was reached in a relatively short time frame of 2.5 years. The PMMR is a great success in micro assembly machines, medical equipment and optical devices.

The company slogan ‘Discover Precision’ remains unchanged. It supports the brand message and our promise to customers that by working with PM they will discover new possibilities.

Our linear bearings, slides and positioning systems are renowned for their high precision. Our team’s expert knowledge of linear bearing technology makes customers discover the new scope to enhance and improve the precision of their machines or devices.

New logo

In December 2017 we introduced our new logo. The new logo represents our innovative nature and aspirational vision for the future. The use of the colour yellow has three functions:

1. As yellow has featured in our logo since the company’s beginnings in 1966, it stands for continuity and over 50 years of history;

2. Yellow is used to accentuate the company’s core competency and main business driver, i.e. innovative solutions based on crossed roller technology (the letter P in the logo). Furthermore, in the design of the letter M one can recognise the V-groove;

3. Yellow stands for energy, happiness, craftmanship and flexibility. These are all values that PM subscribes to, and is recognised for by its customers – as per the results of our recent marketing survey in 2017.

2025

PM goes beyond standard cleanliness protocols with cleanrooms that are equipped with bake-out ovens and Residual Gas Analysis (RGA) systems; tools that are essential for high-purity cleaning and advanced contamination control.

With RGA, PM identifies molecular outgassing under vacuum (such as water vapor and hydrocarbons). Even the smallest molecular contaminants can be detected, ensuring that parts and positioning systems meet our customers’ cleanliness requirements. This is especially critical for industries like semiconductors, life-sciences and medical technology, where outgassing can have a negative impact on the process critical sensitive environments and reduce performances.

Customers rely on PM not only for mechanical precise parts and positioning systems, but also for ultra-cleanliness.

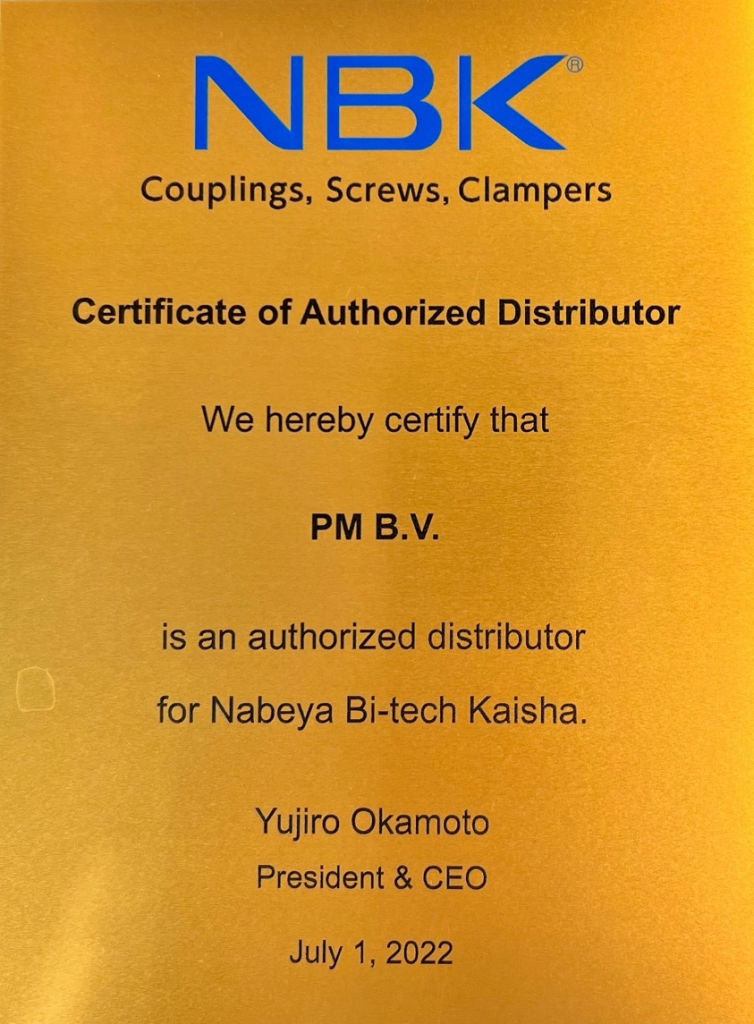

Authorized distributor for Nabeya Bi-tech Kaisha (NBK)

Nabeya Bi-tech Kaisha (NBK), a renowned Japanese manufacturer, specializes in the production of miniature couplings, flexible shaft industrial couplings, and special screws. Since 2003, PM has been a trusted partner of NBK, responsible for marketing and distributing their exceptional products. Both NBK and PM are highly regarded for their commitment to service excellence and product quality.

With a rich history dating back to 1560, NBK initially began as a foundry manufacturer. Today, they boast an extensive range of top-notch shaft couplings, including various styles such as Oldham, Bellows, Jaw, and many others. Additionally, NBK offers several clamping options for coupling and shafts, ensuring a comprehensive selection for customers. Notably, their product lineup also features the groundbreaking XG series, a revolutionary high-gain coupling.

What truly sets NBK apart is its ability to cater to specific requirements, such as cleanroom environments, high temperatures, and ultra-high vacuum conditions. These specialized couplings find applications in various cutting-edge industries, including semiconductor manufacturing, medical technology, and the machine tool industry.

For information about NBK products please contact our sales support by using this email contact.

For visiting the NBK website please use this link.

For information about NBK special screws use this link.

WANT TO KNOW MORE ABOUT OUR PRODUCTS?

Functional Always active

Preferences

Statistics

Marketing

Your catalogue download was successful

Also interested in our e-book?

The e-book is written for engineers and includes tips and tricks for the installation of linear guides

- Design tips from experts

- How to avoid commonly made mistakes

- 7 quick wins which will save you money

- Considerations on lubrication

- Clear illustrations

- Special edition written for the engineer