Innovations that helps you get ahead

Ever since its foundation in 1966 PM has brought a continuous stream of technological innovations to the market. Over the last five decades, PM products have opened up new opportunities for our customers, providing them with technological advantages that helped them to expand their business and drive new product development.

Highly qualified employees

In translating today’s industry challenges into new products, we depend on our highly qualified and driven workforce. Each one of our employees brings in their specific knowledge and a lot of enthusiasm for product innovation.

PM also benefits from its strong relationships with world-leading universities, which ensure we are always operating on the cutting edge of the latest R&D and industry knowledge.

Continuous training, knowledge sharing, and an open culture of collaboration empower our teams to push technological boundaries and deliver creative, high-quality solutions for our customers worldwide.

1990 – RPM radial bearing

In 1990 we introduced the RPM rotary positioning bearing, known for its high repeatability and accuracy in a rotary motion. RPM bearings are made from corrosion-resistant steel and the ring can be ordered with one or more carriages. The carriages use adjustable and replaceable recirculating bearing elements. The bearings enjoy popularity in the measurement and analysis industries for their high repeatability and accuracy. Go to the page with RPM specs.

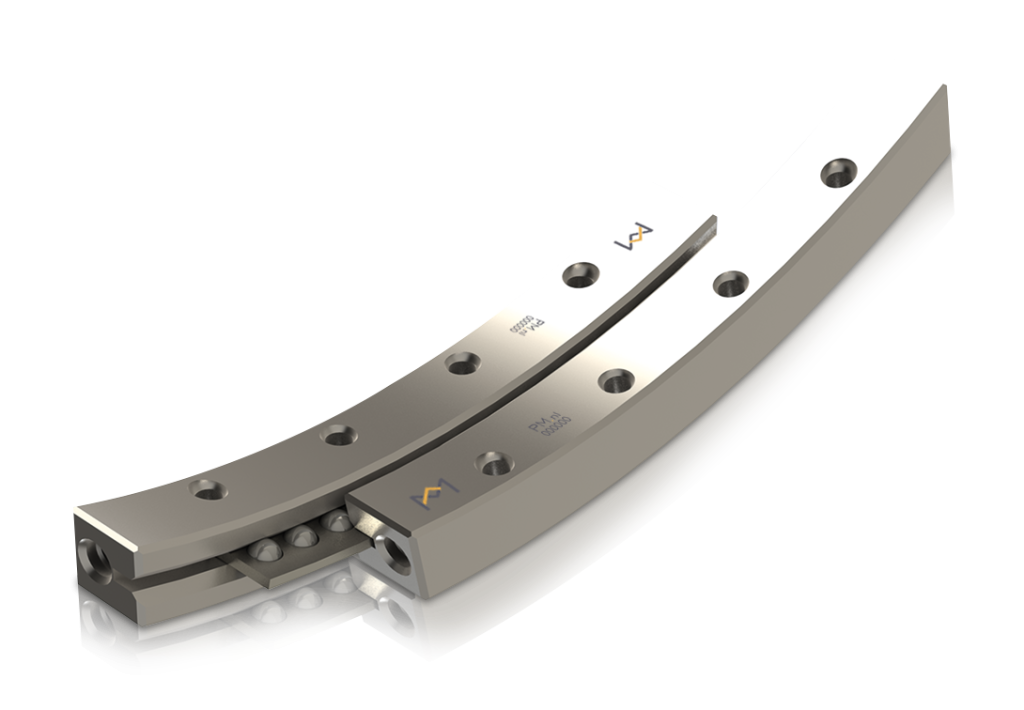

1998 – Gonio bearings RGB

Gonio bearings were originally developed for use in the precision optical lenses industry. Today they can also be found in measuring devices and in semiconductor R&D. The bearings can be supplied either with crossed roller or ball bearing cage assemblies. RGB bearings offer precise angular motion with a low rolling friction coefficient.

In 1999 PM introduced SF-technology – for ultra-smooth linear motion and pinpoint precision.

2001 – ACC-technology

PM introduced the first standardised Anti-Cage Creep system (ACC) as an optional feature for the RSDE deep groove crossed roller bearings. An all-metal design that provides reliable performance in even the most demanding applications. As the system is integrated in the design of the linear bearing without affecting the bearing’s external dimensions, it is possible to replace existing linear bearings with ACC bearings (drop-in replacement).

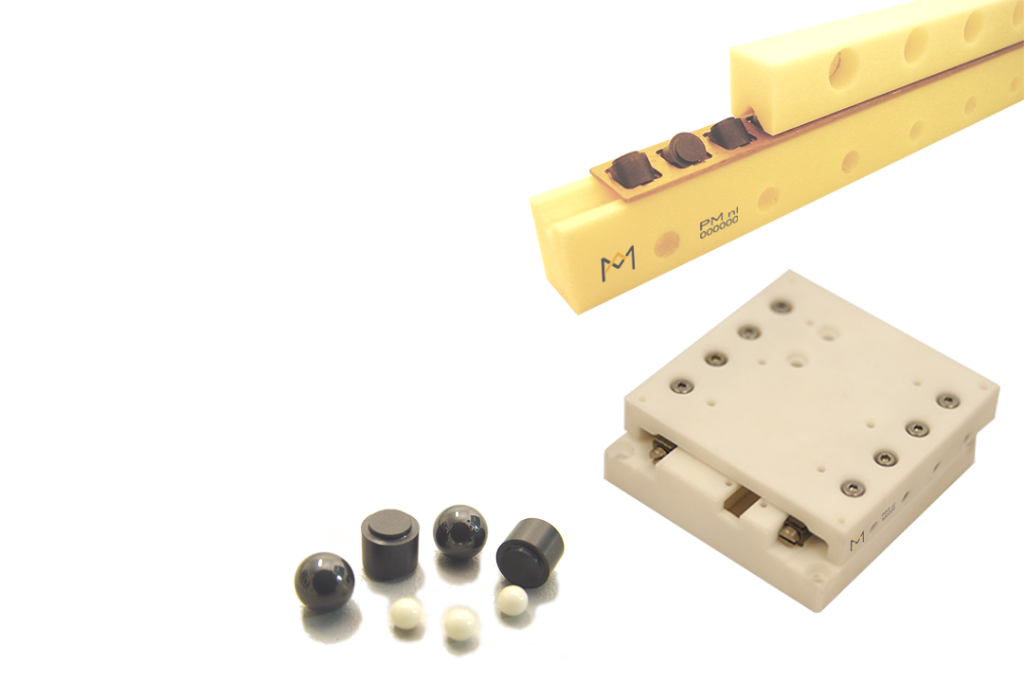

2005 – Ceramic linear bearings

In 2005 PM was the first company to introduce a full range of ceramic crossed-roller linear bearings. Since then we have further gathered superior knowledge of the product and its behavior in industry applications. We are a major supplier of ceramic linear bearings to high-tech markets including medical science and the semiconductor industry. Click here for more information about ceramic linear bearings.

2005 – FMB bearings

Driven by demand from the semiconductor industry, in 2005 PM introduced the flat mounted table bearing series FMB.

FMB was specifically designed for tight spaces, high accuracy requirements and repeatable precision. Due to the height difference between the inner and outer ring, as well as the presence of attachment holes, this bearing is easy to mount. The defined friction force, modified load ratings and a corrosion-resistant design are among the optional features available.

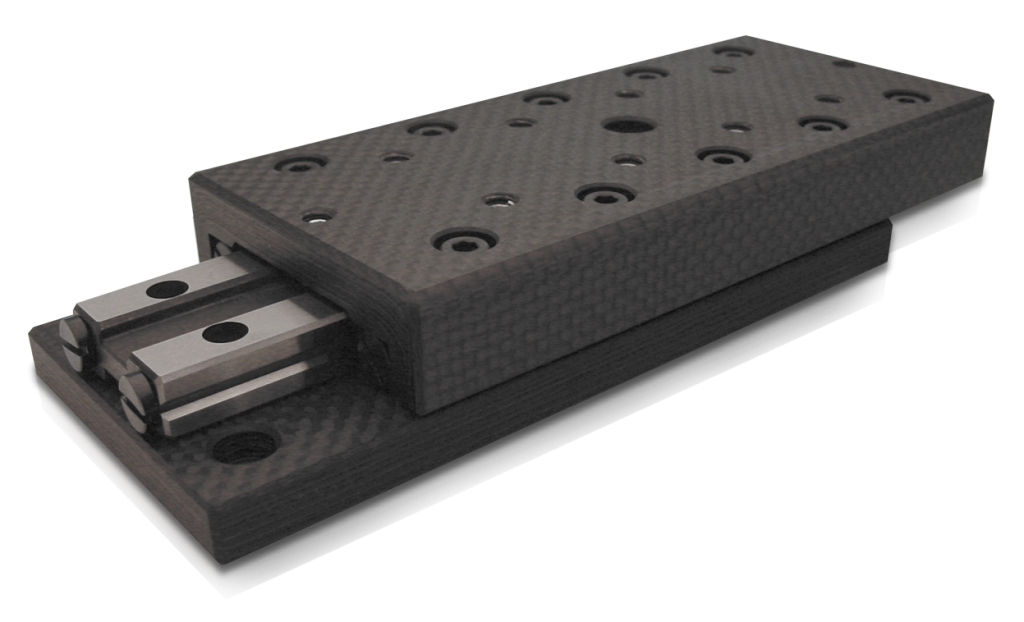

2006 – Carbon fibre composite linear slides

During the Motek industrial fair in Germany in 2006, PM demonstrated the practical use of carbon fibre composite linear slides and introduced a range of carbon fibre frictionless slides.

Technology leadership is the foundation of our business

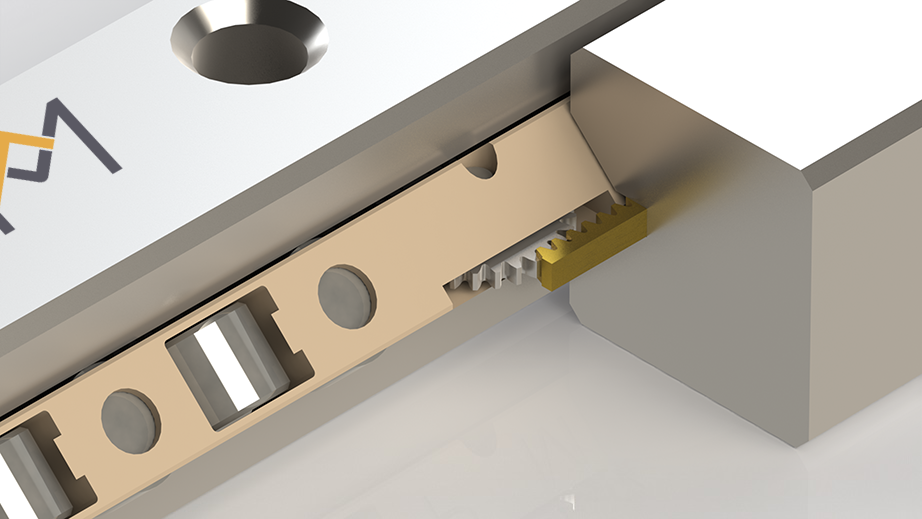

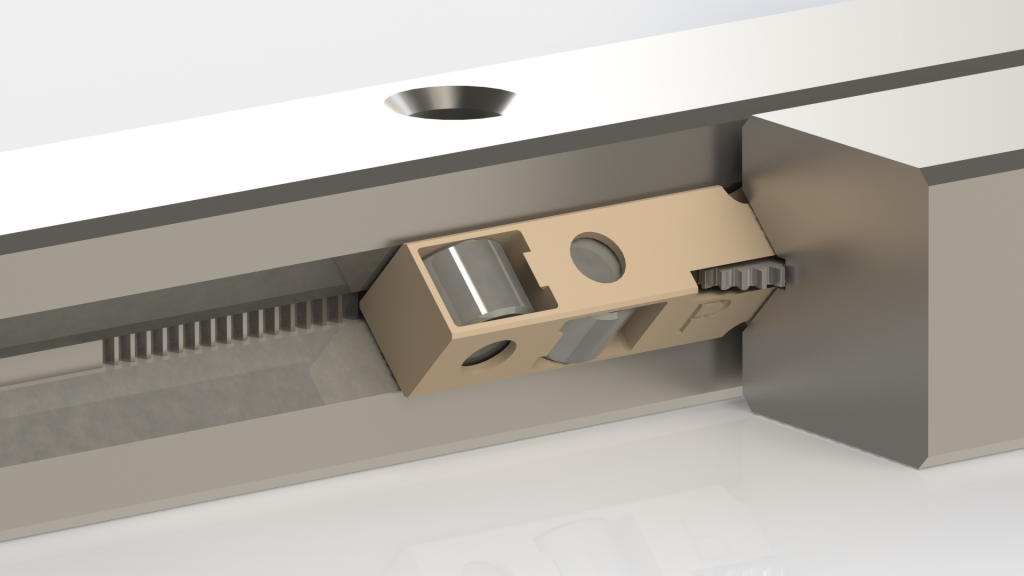

2007 – Next-generation ACC

Six years onwards from its first introduction in 2001, our next-generation anti-cage creep solution was ready for market. The new ACC combines a modified rack system with a high-density KRE roller cage type, providing longer lifetimes and increased load capacity. Anti-cage creep technology ACC is available in the standard linear bearings sets of the RSDE and RNG types. Read more detailed information about ACC-technology here!

2009 – Introducing ACCI for UHV

ACCI for UHV is our anti-cage creep technology for stainless steel RSDE linear bearings. With a rack that is integrated into the through-hardened rail, this solution is suitable for use in vacuum and ultra-high vacuum applications. A roller cage made from PEEK material has been designed specifically for use with this solution if needed.

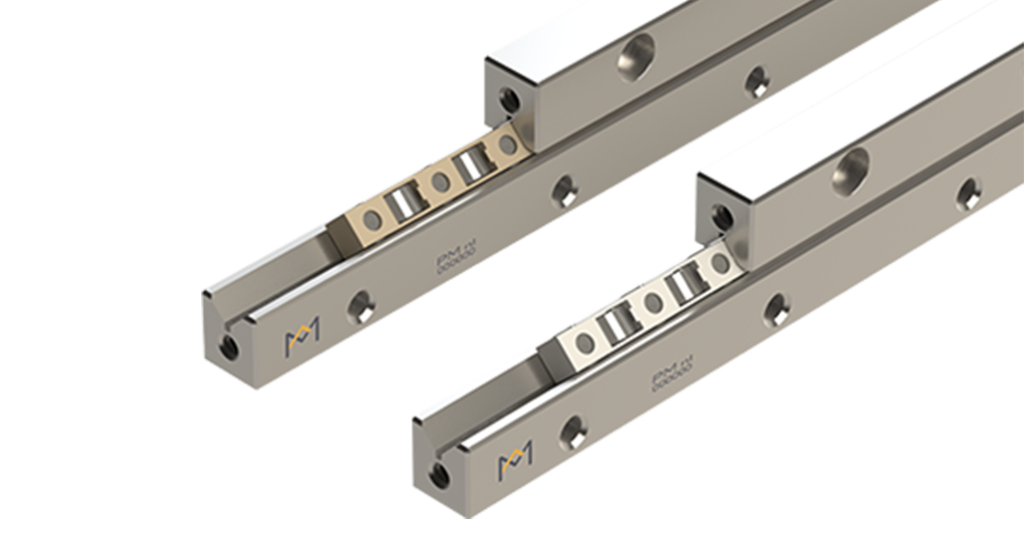

Sets with ACC-technology

2013 – Miniature slide PMMR – World’s 1 miniature slide with crossed roller bearings

The PMMR miniature slide offers high stiffness and load ratings in a compact and stainless steel design. PMMR slides are a popular solution in the medical and semiconductor industries. They meet the smallest space requirements in the market while demonstrating excellent motion performance. PMMR is the first miniature slide in the market using crossed roller bearing technology.

2017 – RNG linear bearing

RNG linear bearings combine smaller assembly dimensions with a 30% higher load rating than any other product in the market. This makes our RNG type the absolute benchmark in precision linear bearings.

2019 – Miniature slide MSR – Anti-cage creep technology included

The miniature slide MSR is developed to meet the requirements of tomorrow’s industry. With faster cycle times, superior quality and high accuracy in a minimum space, the MSR is the product of choice for precision applications that are subject to high accelerations on a constant basis. It include 7 sizes and all parts are made from stainless steel. The stroke is ranging from 5 – 112 mm.

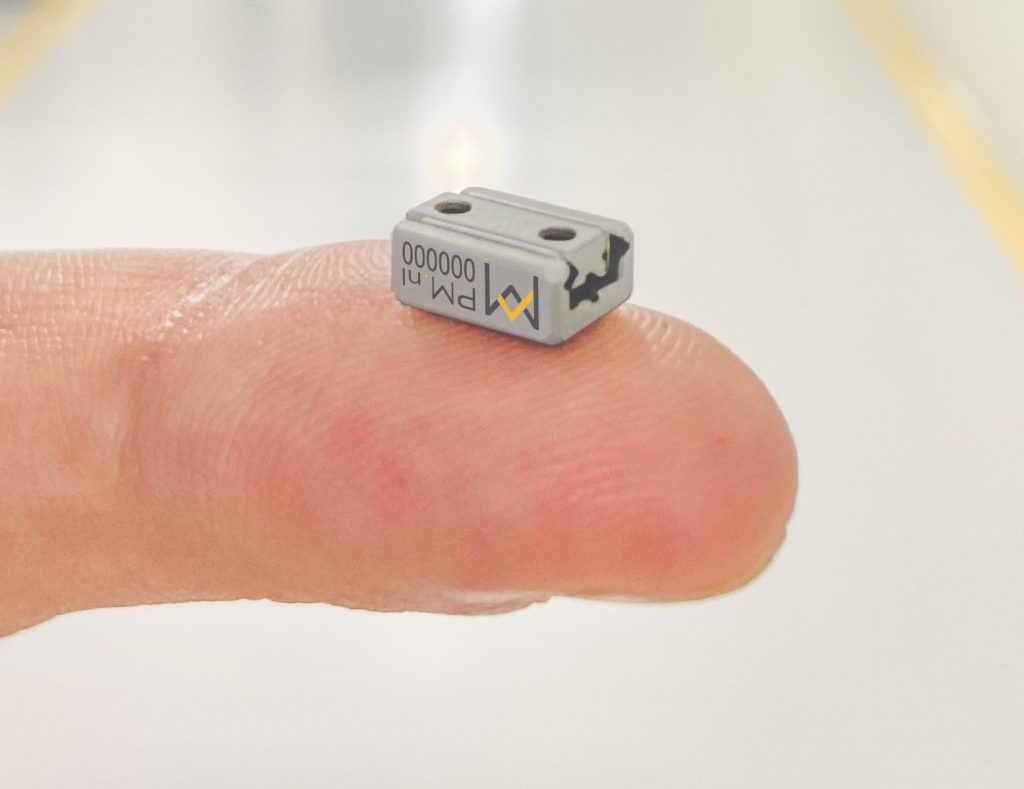

2020 – Smallest miniature slide MSR 3 with anti-cage creep in the industry

With only 3.2 mm of height and a width of 5.5 mm, the new size offers maximum space savings. The new size provides the advantages of cross roller bearings together with anti-cage creep technology in the smallest size available. The MSR 3 offers high precision, stiffness and durability in the most tight installation spaces.

WANT TO KNOW MORE ABOUT OUR PRODUCTS?

Functional Always active

Preferences

Statistics

Marketing

Your catalogue download was successful

Also interested in our e-book?

The e-book is written for engineers and includes tips and tricks for the installation of linear guides

- Design tips from experts

- How to avoid commonly made mistakes

- 7 quick wins which will save you money

- Considerations on lubrication

- Clear illustrations

- Special edition written for the engineer