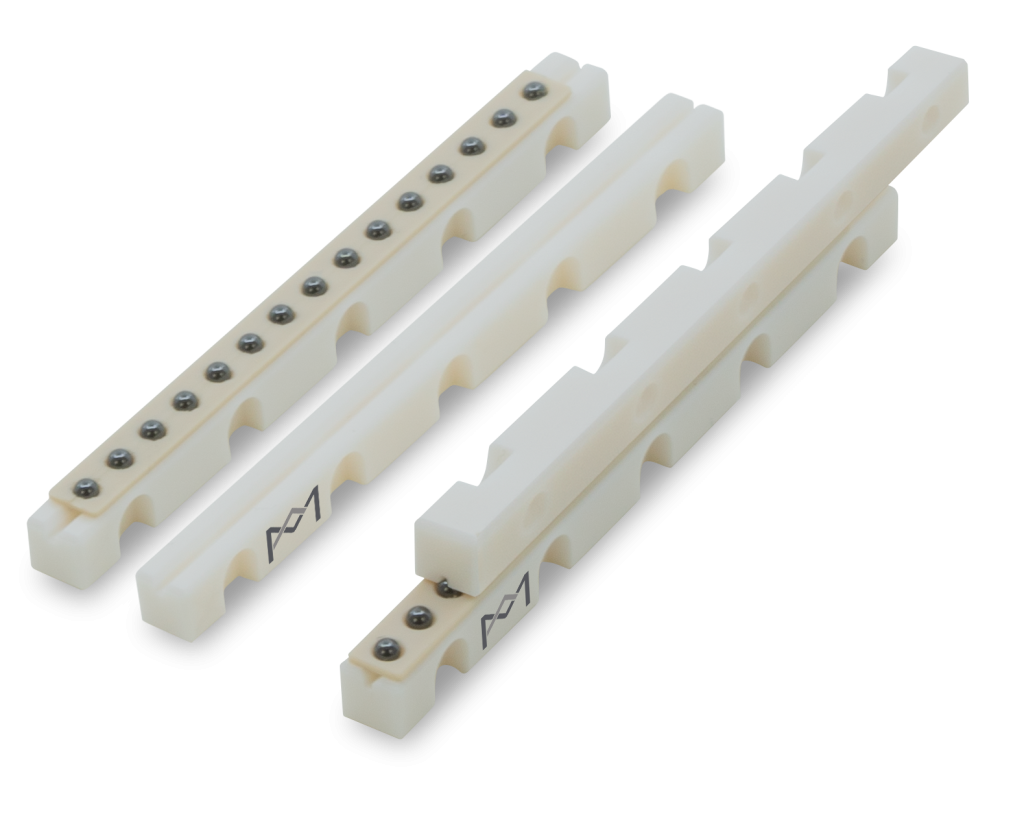

Ceramic linear guides

PM has been supplying linear guide bearings that are fully ceramic, as well as hybrid versions, for decades. In 2005, PM was the first manufacturer to market ceramic linear bearings. On this page you will find general information about the ceramics we use. For more detailed information or advice for your application, please consult one of our experts or your local PM sales partner.

Home » Ceramic linear guides

Why using ceramics in a linear bearing?

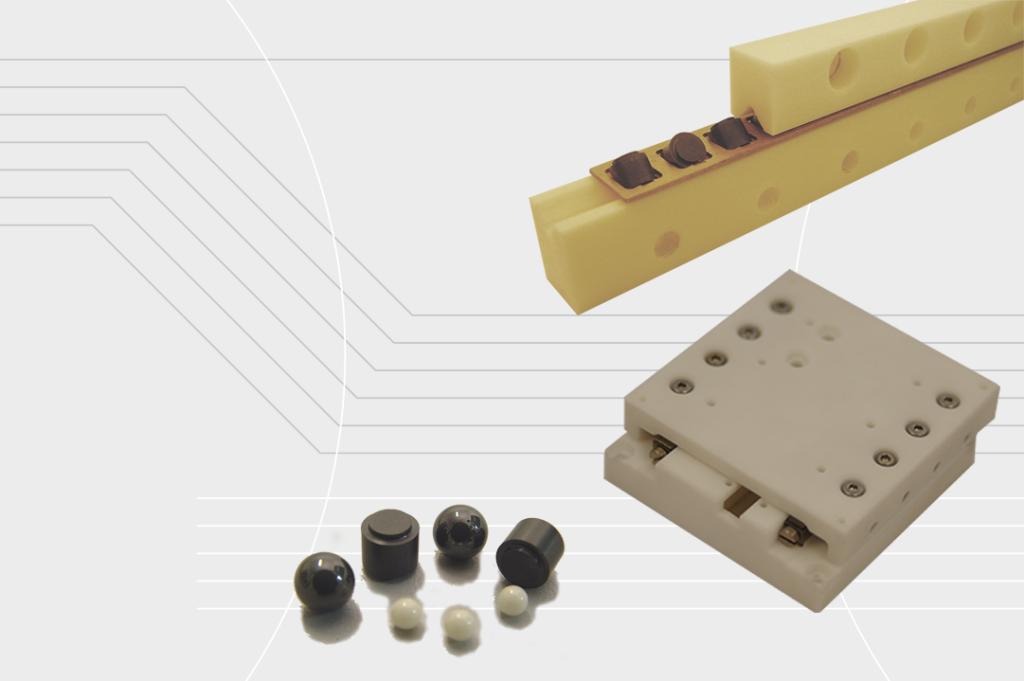

The use of ceramic in a linear guide bearing offers great advantages for certain applications. Ceramics are superior to steel in both density and hardness. Their non-magnetic properties make them ideal for use in non-magnetic or ultra-high vacuum environments, particularly in new-generation machines.

PM engineers have developed numerous ceramic custom designs. The focus remains on solutions that incorporate the silicon nitride (Si3N4) or oxide family (Alumina Al2O3 or Zirconia ZrO2) of ceramic compounds. The selection depends on operating conditions such as speed, temperature, and surface finishing.

You want to use ceramic linear guides?

Send us an email or call us to receive more information about the use of ceramic linear guideways.

Lightweight

Ceramics have a density of about 40% to 60% of traditional bearing steel DIN 1.3505. Since force is directly proportional to mass, low-density silicon nitride significantly reduces the starting force needed to move the slide or stage. This improvement benefits high-dynamic applications where reducing the mass-moment of inertia is crucial.

High Rigidity

Ceramic guide rails and balls (Silicon Nitride and Alumina) have a Young’s Modulus that is about 50% higher than steel. This makes ceramics an ideal material for linear guideways in high-speed XY-stages, like those used in wire-bonding machines in the semiconductor industry. These applications require both rigidity and precision at high speeds.

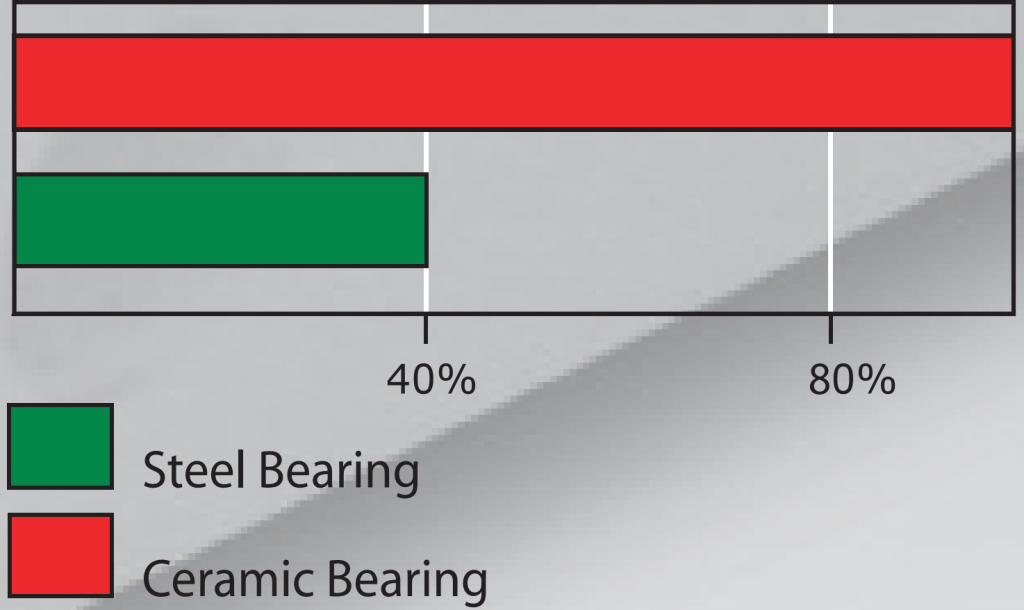

Increased lifespan of ceramic linear bearings

The lifespan of linear bearings is directly linked to hardness, the most critical mechanical property of bearing materials. With an impressive hardness of 78 HRc—twice as hard as many bearing steels—and a compressive strength 5 to 7 times that of steel, silicon nitride significantly improves wear resistance. This minimizes the damaging effects of repeated surface contacts. The lifetime of ceramic linear bearings varies with operating conditions. A lifespan test of steel and full ceramic linear bearings without lubrication is shown in the figure on the left.

Operation at a high temperature

Ceramic linear guides retain their mechanical properties even in extreme temperatures, from cryogenic levels to around 800ºC. This makes them highly suitable as heat-resistant materials.

A major challenge at such high temperatures is lubrication. Oil and grease can be used up to 300ºC, while solid lubricants are effective up to 500ºC. Ceramic bearings, however, can operate at temperatures up to 800ºC, outperforming the best high-temperature bearing steels by a factor of three.

Speed vs Performance

Each ceramic material offers unique benefits due to its specific characteristics. Some perform better at high speeds, while others are more suited for lower speeds.

Additional properties such as vacuum compatibility, lower particle generation (around 1/3 less in both air and vacuum compared to stainless steel), chemical inertness, corrosion resistance, and electrical non-conductivity enhance linear guide performance in specialized applications.

PM engineers can offer custom recommendations based on the demands of your application.

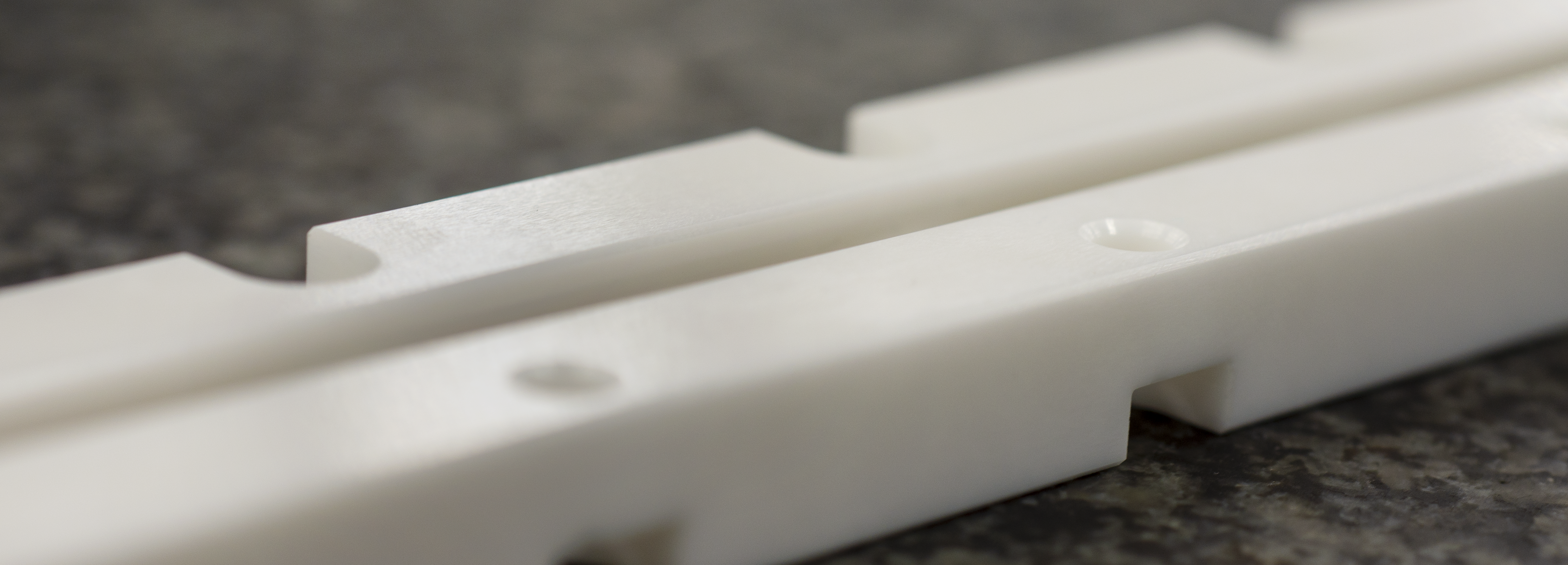

Ceramic linear bearings – designed to client specification

Ceramic linear guide bearings and slides are custom-made to order. This allows the specifications of the ceramic bearings to match your system requirements, including speed, operating temperature, and accuracy. Manufacturing begins only once all technical details are finalized.

PM engineers are available to help you select the right linear guideway and provide the best solution, no matter how complex or unique your challenges are. Contact us for more information about ceramic linear guides.

Let's talk about your application!

WANT TO KNOW MORE ABOUT OUR PRODUCTS?

Functional Always active

Preferences

Statistics

Marketing

Your catalogue download was successful

Download your e-book

The e-book is written for engineers and includes tips and tricks for the installation of linear guides

- Design tips from experts

- How to avoid commonly made mistakes

- 7 quick wins which will save you money

- Considerations on lubrication

- Clear illustrations

- Special edition written for the engineer