Large Machining Excellence

We offer large machining services to produce large-sized and complex parts at tight tolerances for the semiconductor, aerospace and defence industry. Many years of experience in precision positioning stages and the high-tech motion industry has enabled us to supply other complex products as well.

Home » Large Machining Excellence

The industries we serve

Semiconductor

PM has unmatched in-house manufacturing expertise. With a long track record in the semiconductor industry, we ensure consistently high product quality and closely monitor every step of the production process. Especially in the precision machining of large and complex components, we employ innovative technologies that guarantee the highest levels of accuracy and reliability.

Our expertise also provides great flexibility: we can implement design changes quickly and minimise lead times, enabling us to efficiently meet individual customer requirements.

Military and defence

For over 55 years, we have been a reliable supplier to the world’s leading companies in the military and defence markets. PM has grown from a precision machining subcontractor into a leading supplier for complex machined parts and integrated assemblies. We apply the latest defence guidelines on manufacturing.

Our clients are in all sectors of defence: land defence, aero defence and naval defence.

As a key supplier, we are involved in major defence programs such as Radar and security systems, F16, F35, Apache, Chinook, NH90 Black Hawk, Mirage, CV-90 tank, Fennek, Boxer, PzH-2000, Drones, P8, Patriot and ESSM missile defence system.

Our long-term philosophy is to act as a system integrator responsible for engineering, manufacturing, assembly, testing, certification, delivery and supply of logistical support.

Aerospace and space

Parts for aerospace and space are often challenging, complex, and difficult to machine. We work closely with leading companies on ambitious projects in this industry, delivering solutions for highly demanding applications. Our experience spans a wide range of successful space initiatives, including Ariane launch vehicles, large telescopes, and space robotics, as well as the production of landing gears, motor frames and other critical structural components.

This extensive experience ensures that we are exceptionally well prepared to handle your high-precision, complex, and mission-critical components, providing reliable performance under the most extreme conditions.

By combining advanced engineering, precision manufacturing, and stringent quality control, we help bring the most ambitious aerospace and space projects to life.

Large machining additional competences

With the focus on the high tech industry we offer the following additional competences for large machining:

- Material knowledge

- Manufacturing

- Ultra- and extreme-high vacuum

- Cleanroom assembly

These competences are explained in more detail below.

Material knowledge

We have extensive experience with various exotic materials. To name a few:

- Titanium

- Ceramics

- Composites

- Aluminium and its alloys

- Stainless steel

- Inconel

Manufacturing

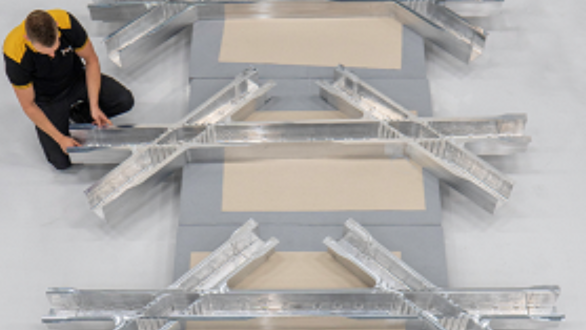

PM’s large machining department is well equipped for the production of complex and large structural components.

The climate-controlled facilities are built to the latest standards. Below is an overview of the machines we use for the large machining services.

Small-sized products as well

Because large machining is part of our business, we have other modern CNC machines available to machine smaller sized parts with sub-micron tolerances. These machines are used for the small-sized linear bearings and slides, which we offer in the catalog and which can be customised.

The picture on the side shows vacuum chambers, an example of a complex and large machined product. Customers are related to the semiconductor, solar, research centres (particle accelerator systems) and the pharmaceutical industries.

The vacuum products range from large products like chambers to small-sized tubes for electron microscopy.

With an in-depth vertical integration in manufacturing, a wide range of manufacturing services is available:

- Turning up to 550 mm OD

- Milling up to 10.5 metres in length

- Drilling

- Heat treatment

- Precision straightening

- Electrochemical machining

- Flat and cylindrical grinding

- Cleaning and assembly

Typical examples of products and structures are positioning stage components, wafer chucks, holders and vacuum chambers for motion systems which we produce in-house.

Since all critical production steps are done in-house, we have full control over every production step and take care of every important detail. With the vertical integration, you can rely on high product quality, more flexibility, lower cost and one main contact person for your project.

Ultra- and extreme-high vacuum

Designing and manufacturing parts for Ultra-High Vacuum (UHV) and Extreme-High Vacuum (EUV) environments require material and manufacturing knowledge and a well understanding of cleanliness and procedures.

Customers in the semiconductor front-end industry, synchrotrons and space industry using strict guidelines to ensure the highest degree of cleanliness for their processes.

As a specialist in the production and assembly of extreme clean structural components, chambers, modules and systems we offer:

- Engineering & design of components

- Accurate machining

- TIG-welding

- Cleaning service (ultrasonic)

- Bake-out of parts

- RGA-qualification

- ISO Class 6 and 7 assembly

- Vacuum leak testing

- Cleanroom assembly

- Qualification and contamination control

- UHV packaging

Cleanroom assembly

Products are baked-out and cleaned before they arrive in our cleanroom(s). Mechanical, electrical and vacuum assembly engineers work in cleanrooms on the final assembly and perform (RGA) and quality inspection, detailed measuring reports and conduct final testings on the products before shipment.

Cleanroom assembly can be performed under ISO class 6 and ISO class 7, providing optimal conditions for sensitive and high-precision products. This ensures that every part, module or system leaving our facility maintains exceptional cleanliness, performance and reliability, even for the most demanding applications.

One-Stop-Shop for Large and Accurate Machining

Large machining centres

Double gantry Matec-40P

This vertical CNC milling machine can handle voluminous workpieces. The video gives an impression of the double gantry machine centre, the Matec-40P.

The stationary machine table enables heavyweight workpieces as the gantries are moving. All moving axes are guided by precision roller profile linear guides for high rigidity and to handle high forces in all directions.

Working area: 10500 x 3400 x 1350 mm.

2-Axis swivel head.

Horizontal machining centre Bavius HBZ Aerocell

The production of large aluminium structural parts demands three things in general:

- A combination of high machining performance

- A skilled machinist

- High output for maximum productivity

This 5-axis machine combines the highest material remove rate output with the smallest footprint. We are able to machine up to 15 l/min. A pallet change system is integrated to permit loading and production at the same time.

Working area: 4000 x 2000 x 750 mm.

Precision machining capabilities with tight tolerances

See how we manufacture and measure parts for space rockets, precision machine frames for semiconductor machines and more.

Questions about your project?

Interested in large machining solutions? Fill in the form and we will contact you to discuss your needs.

Functional Always active

Preferences

Statistics

Marketing

Your download was successful

Request price and leadtime for this item

Your catalogue download was successful

Also interested in our e-book?

The e-book is written for engineers and includes tips and tricks for the installation of linear guides

- Design tips from experts

- How to avoid commonly made mistakes

- 7 quick wins which will save you money

- Considerations on lubrication

- Clear illustrations

- Special edition written for the engineer